Optimize Your Pre Mixing Process

Category : Animal Feed / Posted on : September 15, 2016

A premix is a value added solution to the feed industries, it is a mixture of vitamins, trace minerals, medicaments, feed supplements and diluents etc., The prime objective of the premix industries is to manufacture high quality premix consistency product, efficient and economic, to deliver the micro ingredients as per the consumer desire.

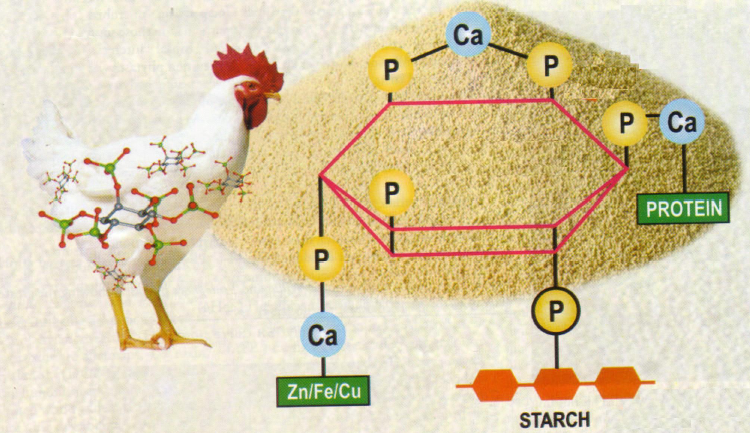

Vitamin: vitamin account for approximately 3% of the total ingredients cost for broiler chickens, vitamins are required for normal metabolism in animals and consequently are essential for optimum health as well as normal physiological functions such as growth, developments, maintenance and reproduction. Most of the vitamin cannot be synthesized by poultry in sufficient amounts to meet physiological demands, hence they must be obtained from the diet. Vitamin sources Yeast- B complex, Fish oil-Vitamin A,D.

Supplementary feed with vitamin by means of formulated premix in accordance with optimum vitamin nutrition is the safest and most economical way to maintain a high level of welfare and health as well as to achieve good performance and high product quality in poultry production.

Trace minerals:

Minerals and vitamin incorporation in the feed is 5-50gms per ton of feed. Trace minerals plays a critical role in the immune system, egg formation, fertility and enzymes function in poultry, the share of the trace minerals in the feeds cost is only .5% but their contribution is shaping the performance and profit is very higher. Hence the premix manufacturer responsibility is to deliver the preciously homogeneously mixed product, keeping in mind the minute amounts and their deficiency will cause severe derangements.

Medicaments: Today, poultry is reared intensive condition, since there is a manifold risk of infectious, to keep bird healthy, the rely on medicaments is very high which promote growth by warding off infectious, at low dosage in premix formulation demands to reach the final feed of high degree homogenous blend uniformity to improve feed efficiency.

Feed Supplements: High level of production and efficient feed conversion are the need of modern poultry industry. Hence in recent years, there has been a flurry interest in supplementing the other non nutritive substance in micro levels such as acidifiers, probotics, enzymes herbal products, micro flora enhancers, carotenoids etc., hence it poses a great challenges to the nutrionists, premix formulators and the industries to deliver preciously blended homogeneous mixed product.

Selecting the Right Mixing Equipment and optimizing Feed Premix manufacturing process is the most important decision making steps to achieve the consistent, high quality premix products.

Diluents or Carriers : Better premixes can often be formulated and prepared with a blend of predetermined raio of several diluents rather than with just one. Types of carrier commonly used in the formulation of premix are either organic such as Wheat middling, rice hulls corn cob, ground corn, Soya tobean meal, lactose or inorganic such as Calcium carbonate, Dicalcuim phosphate, Mono calcium phosphate ,Zeolite, fine dried salt etc.,

Mixing : The mixing process is the heart of any premix manufacturing unit., the varied characteristics of the ingredients and the proportion to meet the customized formulation, the selected mixing equipments must be able to provide hematogenous mixtures of physically adverse particles incorporated at various levels in the mix, the important mixer requirements are: Affords good homogeneity with the component included at lowest possible content.

Mixing has been a major problem for feed premix manufacturing industries for the last century. Why has mixing been a problem? because of varied particle size, density , etc and the characteristics of ingredients need to blend leads to gravity and percolatio problems.

The Fact of Toshniwal Mixer

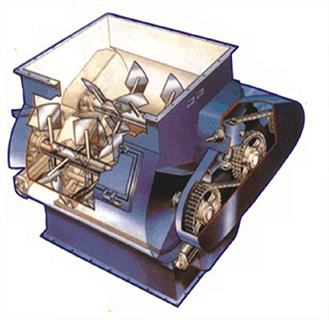

Toshniwal Mixer is a new generation mixing technology available in India with the below said striking features for the demanding precision Mixing and also to provide homogeneous mixtures of physically adverse particles incorporated at various level in the mix.

- Freedom of movement

- Transport capabilities of the particles

- Weightless condition

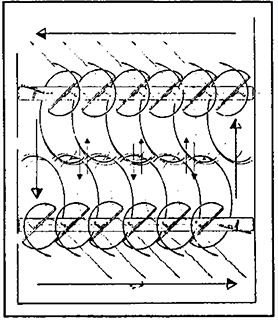

The fluidized zone mixer comprises a series of paddles affixed to two shafts positioned in a double-drum housing. The shaft rotate in opposite direction at a specific peripheral speed. The paddles are angled and overlap in the middle of the mixer. The paddles also create whirls and eddies in the weightless material, hence mixing the materials thoroughly before they have a chance to segregate, affords good homogeneity despite powder / liquid component included at lowest possible.

The mixing equilibrium

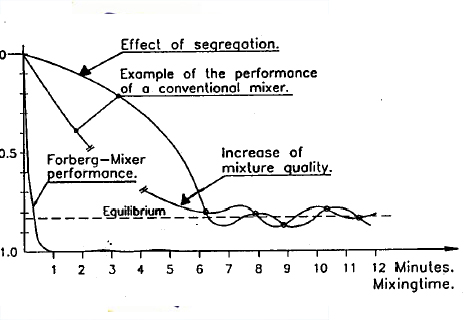

Generally when the mixer starts moving the material will start being mixed. As soon as it starts being mixed, it will start segregating, because the movement of the particles in the mixture, promotes percolation, hence segregation.

After some time, the mixing quality increases. At the same time, the rate of segregation forces are stronger than the mixing forces, and the quality goes down, while the segregation continuous to increase. When the quality is so much poorer that the mixing ability of the machine overcomes the segregating forces, there will be an other increase of the mixing quality. That is the reason for the waxy cycles in the analysis when the mixer is run longer than necessary.

The Article Emphasis the various feed premix product, importance of mixing homogeneity and the appropriate mixing technology in use.

On the same graph is shown that the Toshniwal mixer perform straight to top quality and barely has any deviation from the equilibrium.

The equilibrium in Toshniwal Mixer is so close to a perfect mixture that the possibility for big variations is not existing. One has to remember, that 60% of the material is weightless and can not segregate. The segregation can only take place in the 40% of the material in the transport zone, but the particles are continuously brought from the transport zone to the fluidized zone in less than 1s, so there is no time for segregation.

Liquid Addition

It is relatively coarse material is to be coated the liquid can just be sprayed or poured into the fluidized zone. It will immediately coat the surface of the particles in the machine and the mixture can soon be discharges.

If very fine particles are to be coated, the liquid has to be sprayed in as a very fine material with assistance of the flow distortion bar. This will throw a curtain of material above the paddle system and prevent the paddle system from being smeared up with liquids.

This flow distribution bar system is especially important when sticky liquids like syrups or other thing which may tend to stick to the steel are to be added, this smearing up the machine.

Emptying & Collection

Most mixers are emptied through a small hole in the bottom. This will create a cone during emptying. This cone will result in severe segregation while the material slides out.

To prevent this effect, the Mixer is equipped with two full length bottom doors for discharging the mixed material.

The subsequent problem to empty the hopper by mass flow to prevent segregation during the emptying to any case, the better the quality is in the bin, the better the chance to keep that quality all the way into the packing system. The best would be to discharge directly into the silo above the packing material, providing for maximum quality.

Conclusion

Inadequacy of conventional mixing equipment and the growing demands of precision mixing of the consumer desire forces the premix manufacturing industries look out right mixing equipment to full fill their needs, opportunities and updating mixing technologies in current and prospective business can be identified at an early stage and should be implemented.

Further details from:

M/s. Toshniwal

267 Kilpauk Garden Road Chennai – 600 010, INDIA

Phone : 91-44-26445626 / 26448983 / 26448558

Fax No. : 91-44-26441820

Email : sales@toshniwal.net

Web : www.toshniwalindia.com