The Toshniwal continuous mixer shares the same advantages as the Toshniwal twin-shaft batch mixer. It is gentle, has low energy consumption, high capacity, lesser space requirement and flexible filling level. The average retention time is approximately 60-120 seconds, making the throughput very significant.

It is very important to control the accuracy of the feeding / dosing system of the ingredients to get your desired quality product after mixing. Therefore, the feeding variation is bare minimum and kept within the tolerance level.

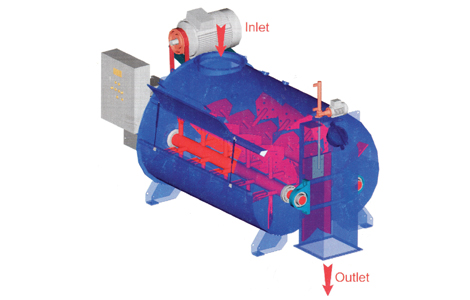

The product fed through the inlet after mixing, passes an overflow wall inside the machine’s mixing zone before it reaches the outlet. There are high demands to the dosing accuracy of the products to be mixed in continuous machines.

The efficient transport system is achieved by having two parallel shafts with blades welded on. The number and position of the blades are of utmost importance. A mechanical fluidization is created in the mixer by critical peripheral speed of the paddle system. The rotor overlaps in the centre of the mixer, making the paddles completely sweep the bottom, and mix all the material at the same time. This has been proved in many experiments. So once a weight less condition is achieved during the mixing process, there is no segregation whatsoever.